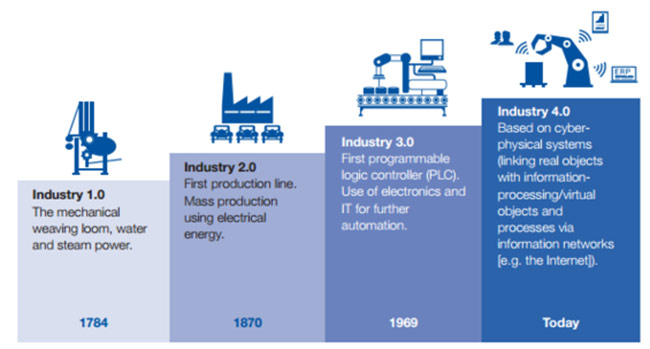

Industry analysts, governments, and forward-thinking manufacturers are all looking forward to the next major shift in manufacturing: “Industry 4.0,” or more commonly referred to as smart factories, as the way ahead for the industrial sectors of economically advanced countries. Called “the fourth industrial revolution,” it’s all about moving from automated systems to cyber physical systems with increased connectivity between machines, computers, and human operators, the Internet of Things, and big data management. Automatic work piece loading, networking CNC measuring machines, and networked and adaptable metrology equipment are all moving toward a radical elimination of defects and faster quality assurance.

Whether or not you have “smart factory” status in your sights, greater connectivity and precision are the future of manufacturing in all sectors, from automotive and aerospace to medical and electronics. Depending on the kind of work pieces you produce in your shop, you need a specialized arsenal of metrology equipment that’s designed for the task, whether that means precise and accurate bridge style machines, larger gantries, vision systems, laser scanning, or portable arms. Better metrology reduces your defects and, when implemented with a smart strategy, can work seamlessly with your production line without bottlenecks.

Saving time at the programming stage is essential to reducing inspection bottlenecks, especially with programs like PC-DMIS CAD that allow you to program inspection routines from CAD, before you have even produced your first part. Waiting for that first work piece to be finished for inspection is a constant headache, but you can make the process seamless with the right training. Metrology dealers like Canadian Measurement Metrology (CMM) offer various levels of PC-DMIS CAD training courses in E-learning packages. With an E-learning package, you improve your operators’ retention rates, give them access to an important reference library for less-used tasks, and keep them in the shop during their training.

DataPage + SPC is another important software to implement if you’re seeking greater connectivity in your factory, as it collects all the data gathered by your coordinate measuring machines, vision systems, gages, and calipers into one database. Available from metrology vendors like CMM, it makes the migration of data seamless and even enables operators to view incoming data in real time, meaning they do not have to be present to physically watch machines perform their inspection routines.

Finally, you have to make sure that your shop has the right combination of tools to provide high speed accuracy and eliminate defects. For some shops, that means shop floor coordinate measuring machines, portable arms, vision systems, or a combination of different technologies for different workpieces. You can browse through all kinds of CMM equipment from Cmmxyz.com, learn about specifications, tolerances, maximum weight loads and range, and find videos of used equipment in action. Metrology is a key factor in the smart factory of the future, but even if you’re not preparing for Industry 4.0, a coordinate measuring machine is a sound investment in your shop’s future. Contact a metrology dealer and start meeting the tighter deadlines and higher accuracy your customers expect.